Cleaning, Picking, and Carding the Wool

The sheep are sheared in the spring, and their fleeces are skirted and sorted. “Skirting” removes any low-quality or especially dirty wool.

Then I hand-process most of the fiber to various stages, since buyers desire different things : some want the wool washed/picked/carded, and some want it already handspun into yarn. Some want wool ready for needle-felting. Some prefer natural colors, some want dyed. My Etsy shop has all the current available options.

For cleaning the wool, I first soak the fleece overnight in cool water. Then it is rinsed 2-3 more times until the water is fairly clear.

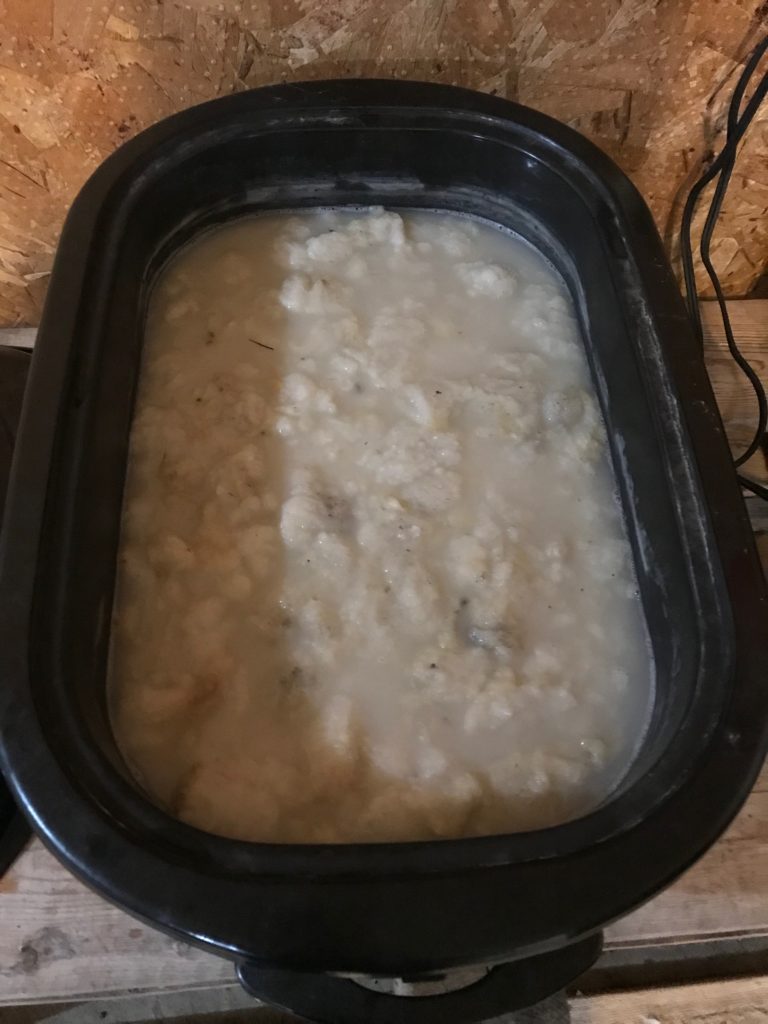

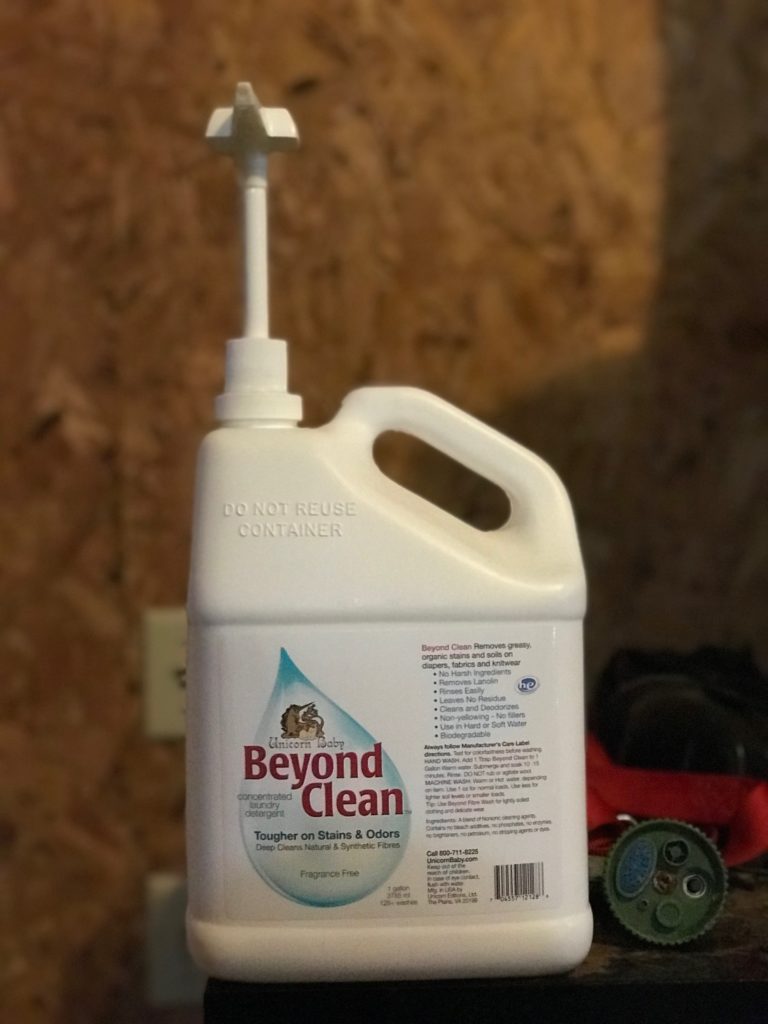

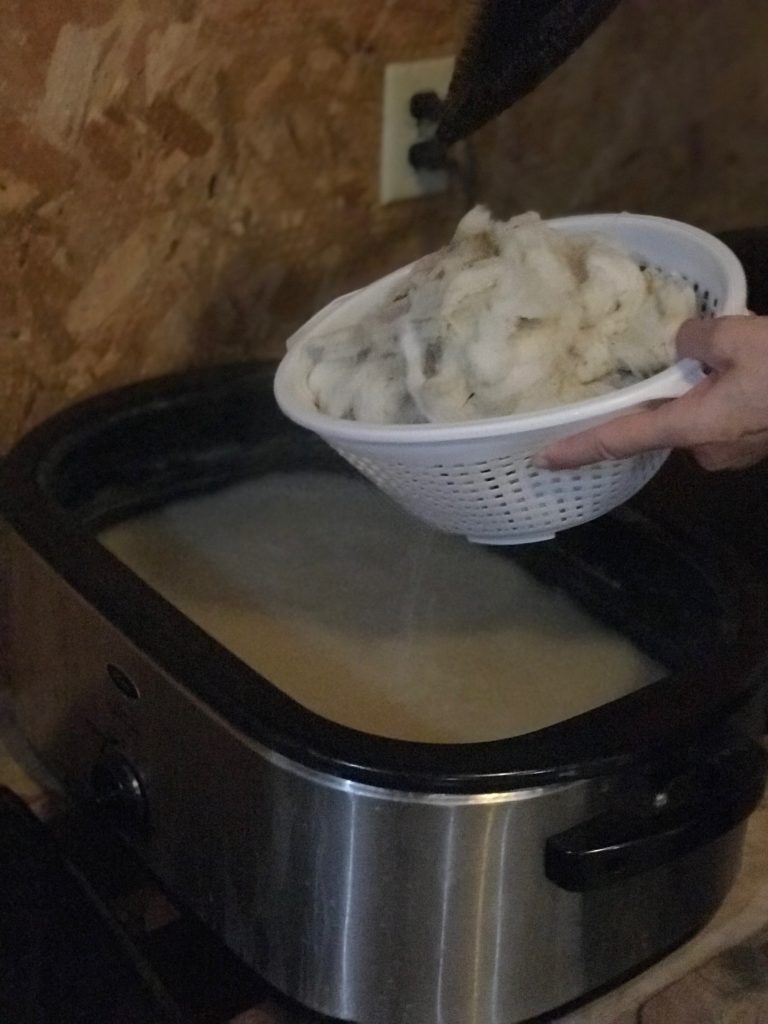

Then the water is drained from the wool. At this point, most of the dirt has been removed. The next step is to remove most of the lanolin and do a deeper cleaning. For this I use turkey cookers to heat the water to just below its boiling point, add UNICORN Beyond Clean and wash about 4 oz. of wool at a time.

After 20 minutes in this hot soak, the fiber is removed and drained.

The wool is put in lingerie bags (about 2 oz. per bag) and then placed into my washer that has already has hot water in it. The bags are pressed under, gently circulating the hot clean water through the wool. Then the washer is set to drain and spin (no rinsing). Next the bags are removed, and the washer is again filled with hot water, but this time about a cup of vinegar is added. The bags of wool are placed back in the vinegar/water and it is allowed to sit for about 10 minutes. Then I drain and spin them. (There is no need to rinse out the vinegar, and there will not be an odor later.)

Then the wool is placed on towels to air dry.

After several hours, I remove the towels and start flipping the wool routinely on the tile floor until it is completely dry.

At this point, the wool has simply been washed, removing most of the dirt and lanolin. But much of the vegetable matter (bits of hay and seeds) still remain.

Next, the wool is picked, picked and picked some more by hand.

This is VERY time-consuming and tedious since the sheep accumulate a fair amount of vegetable matter in their fleeces and their wool is notorious for clinging to everything!

Picking also causes the wool to be pulled apart, fluffed up. This helped “open” it, helping the next process (carding) to go smoother. This next picture is a close up of the picked wool. As you can see, some small particles remain, but most of the vegetation has been removed. Most of the remaining vegetation will drop out during carding and spinning.

Carding is done next. At first glance, it seems like the purpose would be to align the fiber in the same direction. But Babydoll fiber can never be truly aligned due to its naturally random crimp.

Many people like to spin it from a “woolen” method of carding, which means aligning the fiber is not important at all. In fact, if it is hand-carded, spinning from the sides of the resulting rolags (little rolls or tubes of fiber) means the fiber lies perpendicular as the twist enters it. This gives the resulting yarn even more loft. That is the purpose of spinning the “woolen” style–yarn with a lot of loft and cushion. However, no matter how it is spun, the resulting yarn from this wool is wonderful for garments that keep us cozy in the winter. So the main purpose of carding this wool is to make it uniform (no clumps) and easier to manage during spinning.

I sell carded wool at this stage to hand-spinners and needle-felt artists in my Etsy Shop.

Babydoll wool is naturally so crimpy and elastic, you can see why the resulting yarn will have plenty of cushion!